Boosting productivity and extending product lifetimes

We enhance the capability and productivity of your toolset and extend tool-lifetime by upgrading your existing equipment to lower costs or meet the process requirements for your next generation products.

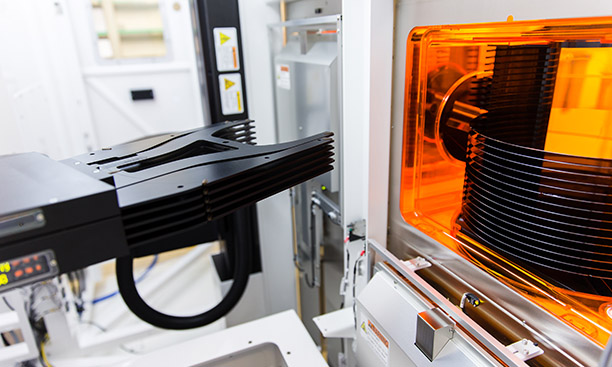

Upgrades are offered for a range of Lam Research products, including plasma etch, thin film deposition, photoresist strip, and wafer cleaning systems. Our upgrade portfolio includes options to maximize the capability as well as productivity of the installed base. The following types of upgrades are available:

Technology Upgrades are designed to extend the useful lifetime of the installed base by upgrading existing equipment to process next-generation products:

- Asset Management – convert under-utilized assets to optimal configuration required by fab production requirements

- Node Extension – convert installed base tools to later generations to meet advanced process requirements

Productivity Upgrades enhance system output of good product by increasing uptime, throughput, and yield at lower operational costs:

- Uptime – increase overall system availability by improving reliability and serviceability, extending preventive maintenance cycles, and reducing maintenance time

- Throughput – increase tool output by reducing non-productive time, reducing recipe time, and optimizing wafer flow efficiency

- Yield – increase output of good product by reducing defects, excursions, and scrapped wafers

- Green – support customer green initiatives and regulatory compliance by conserving energy and reducing gas usage as well as reducing perfluorocarbon (PFC) output

For additional information, please visit MyLam® or contact your local Lam Research representative.