精确测量,洞察工艺

质量计量技术用于测量质量在沉积、刻蚀和清洗工艺实施之后的变化,从而对这些经常被重复的核心制造步骤实施监测和控制。对于薄膜堆栈、高深宽比结构、复杂的3D架构等设计组件,光学技术能力有限,难以准确测量较厚、较深或非透明的构件。测量这些应用中的质量变化是一种简单直接的高精度解决方案,可以用于监测和控制偏差容忍度极低的先进器件结构中的关键构件。

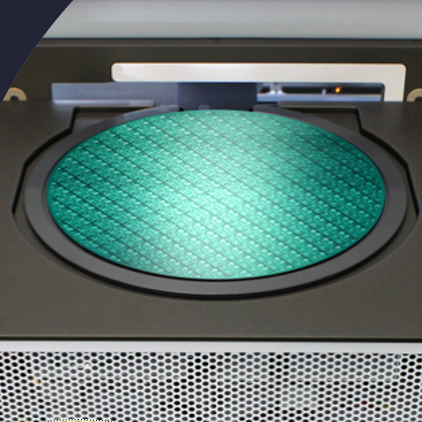

泛林集团的高精度质量计量系统系列可以实时在线监测和控制沉积、刻蚀和清洗步骤——记录质量的微小变化,对潜在的工艺流程偏差进行先进检测。

Related Blog Posts

-

Mass Metrology Applications Grow With Vertical Scaling

Jan 18, 2024In their ongoing effort to pack more computing power into less space, chip manufacturers are adopting scaling approaches that extend designs and stack components vertically—a major shift from the drive to shrink features horizontally that has dominated the industry for decades. This is especially true for memory devices like 3D NAND. To ensure the performance of these vertical designs, the dimensions of the thick film stacks and the high aspect ratio (tall and narrow) features must be tightly controlled, which requires precise measurement.

-

Metryx Marks 200th Tool Shipment With Classy Donation

Feb 2, 2023What is Metryx? Metryx develops and builds mass metrology tools for semiconductor manufacturers that monitor changes in a wafer’s mass as it goes through the wafer fabrication process. Why it matters: Metryx’s sensitive tools measure the weight of a silicon wafer before and after conducting some processes on the wafer, such as cutting pathways for the integrated circuit. The ability to accurately measure the weight change helps determine whether the operations were correctly completed, so the wafer can move to the next process step.